As the latest flagship mobile phone released by Meizu, Meizu 16th uses the Qualcomm Snapdragon 845 processor, and uses copper tube heat dissipation in the mobile phone heat dissipation, so that the mobile phone has a better heat dissipation effect, and the mobile phone runs more stably and smoothly during games. Meizu 16th has also changed its design, not using a metal machine design, but using a 3D four-curved glass back cover, and controlling the thickness of the fuselage to 7.3mm, making it the thinnest under-screen fingerprint recognition mobile phone on the market.

Meizu 16th uses a glass back cover, and the back cover is fixed on the fuselage with double-sided tape, so when dismantling the back cover, it needs to be heated with a hot fan, and the hot double-sided tape can be melted to separate the back cover.

After heating, you can use a pick to separate the fuselage of Meizu 16th. Since the back cover is made of glass, the separation process should be very careful to avoid damage to the back cover glass.

The internal deconstruction of the Meizu 16th can be seen by separating the back cover. The PCB of the Meizu 16th also has a protective cover covered with plastic.

Meizu 16th uses a classic three-stage design, the top of the phone main board, the middle is the battery, the following is the small board, this design for Meizu to have been quite mature.

The back cover of Meizu 16th has been repeatedly polished, and the nano-scale 7-layer vacuum coating technology has been applied to the glass, allowing the 16th to achieve a nearly ceramic-like texture.

Open the protective cover of the bottom small board to see the small board PCB of Meizu 16th, which is mainly responsible for the connection of various interfaces of Meizu 16th and the connection of the external speaker of the mobile phone.

The small board of Meizu 16th also has an important function, which is to connect the horizontal linear motor mEngine of Meizu 16th to achieve a richer vibration effect.

Meizu 16th still continues this mEngine design and has been upgraded to bring a new algorithm that automatically adapts the touch according to the scene, provides feedback such as simulated heartbeat, scroll wheels, etc., and more ringtone music rhythm vibration.

The upper PCB of the Meizu 16th is also covered with a protective cover, and it can be seen that the dual camera of the Meizu 16th is the lower camera, which is the main camera.

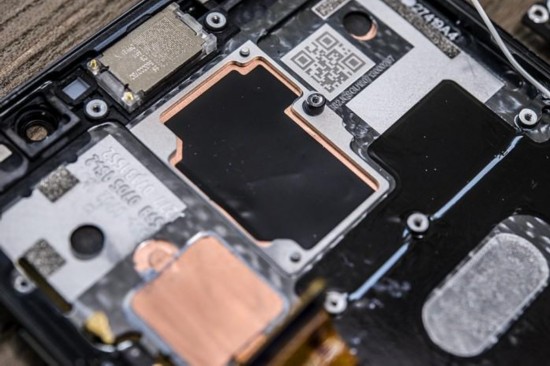

The main board shield of Meizu 16th is covered with a graphite heat-conducting film, which allows the heat of the main board chip to be brought to the fuselage.

After taking out the main board of Meizu 16th, you can see the heat conducting tube on the middle frame of the mobile phone, and the CPU position on the main board is coated with thermal grease.

After removing the main board and battery, you can see the deconstruction of the middle frame of the mobile phone. Meizu 16th uses an aluminum alloy middle frame. The aluminum alloy material is lighter and is currently the material used in the middle frame of the mobile phone.

There is an opening in the middle frame of the mobile phone. Here is the under-screen fingerprint recognition module of Meizu 16th. Meizu rotates the fingerprint recognition sensor at an angle of 13.7 to eliminate moiré patterns. Therefore, the stacking of internal components of the mobile phone needs to be redesigned.

There is a heat conducting tube embedded in the middle frame. The position where the heat conducting tube contacts the CPU uses a whole piece of copper sheet to increase the heat conducting area. Meizu customized a 0.4mm thick heat dissipation copper tube. When the mobile phone is higher than the critical temperature, the water vapor in the heat dissipation copper tube will follow the capillary structure to take heat away from the main board. And when the water vapor cools down and liquefies, it will start to circulate back, which can bring better heat dissipation effect.

In addition, the middle frame of the mobile phone has a layer of copper foil in addition to the aluminum alloy material, which can better absorb the heat on the main board of the mobile phone and achieve better heat dissipation effect.

Meizu 16th built the handset into a small gap at the top of the fuselage, reducing the front opening of the fuselage, maintaining Meizu’s consistent minimalist and symmetrical design language, while also making the whole machine more visually integrated.

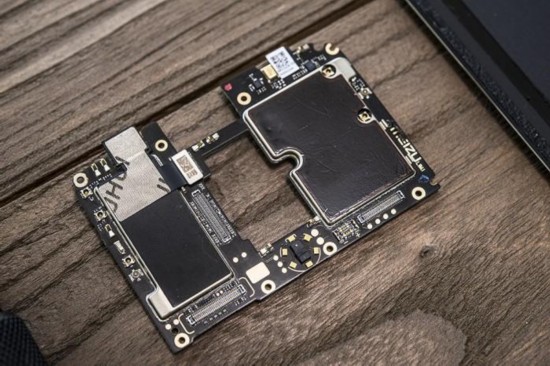

Meizu 16th main board shielding cover can not be removed, this design advantage is to make the shield cover become thinner, bad place is to increase the difficulty of maintenance.

The back of the main board is mainly the CPU and power module of the mobile phone, and the shielding cover is also attached with graphite heat conduction stickers, and the shielding cover here cannot be removed.

Tear off the heat conducting sticker at the CPU position to see that the CPU of the mobile phone is also coated with silicone grease, which is to increase the heat dissipation effect of the mobile phone.

The CPU can be seen by wiping off the silicone grease. The Meizu 16th uses a Qualcomm Snapdragon 845 processor, and the processor and the memory chip of the mobile phone are double-stacked, so only the memory chip of the mobile phone can be seen. The CPU is soldered under the memory chip, and double-stacking can reduce the PCB area occupied by the chip.

Meizu 16th uses a 20 million pixel front-facing camera. Since the forehead position of Meizu 16th is only 7mm, the general front-facing camera module cannot be installed on Meizu 16th. Meizu specially customized the world’s smallest front-facing camera module for Meizu 16th. Customized design from hardware and optical components, and finally created the world’s smallest front-facing camera module, so that the forehead position of Meizu 16th can have such an ultra-narrow design.

Meizu 16th uses 12 million + 20 million pixel camera design and uses ring LED fill light to enhance the photo experience. At the same time, the 16th uses Sony IMX380 + IMX350 sensor, which can provide 3x lossless zoom and large aperture blur effect. The IMX380 sensor is also used on Meizu 15. This CMOS has been tuned by Meizu and used on Qualcomm Snapdragon 845 ISP to bring better shooting results.

Through disassembly, it can be seen that the internal workmanship materials of Meizu 16th are quite excellent. In particular, the heat dissipation design of the mobile phone is very careful. A layer of copper foil is added to the middle frame, and a graphite thermal conductive film covers the PCB. At the same time, a heat conducting tube is used to dissipate heat. Moreover, silicone grease is also applied to the position of the CPU to enhance the thermal conductivity effect. Such a design is relatively rare. In addition, the internal stacking of the entire mobile phone is quite careful, the purpose is to reduce the thickness of the mobile phone and bring a better feel. Overall, for a flagship mobile phone of 2698 yuan, such workmanship materials are still quite valuable.